In a recent announcement, Schneider Electric, the global energy management and automation provider, has made public its new contract to provide comprehensive process automation systems, solutions and services to Dangote Oil Refinery, a subsidiary of African business conglomerate Dangote Group. Under the terms of the agreement, Schneider Electric will supply its EcoStruxure system architecture and platform, comprising its EcoStruxure Foxboro distributed control system, Triconex process safety solutions, PIONIR analytical fuels blending systems and a suite of SimSci and Wonderware software solutions, including its unified supply chain management and operations management software, to drive supply chain and operational efficiency, reliability and profitability improvements at Dangote's greenfield refinery in Lagos, Nigeria.

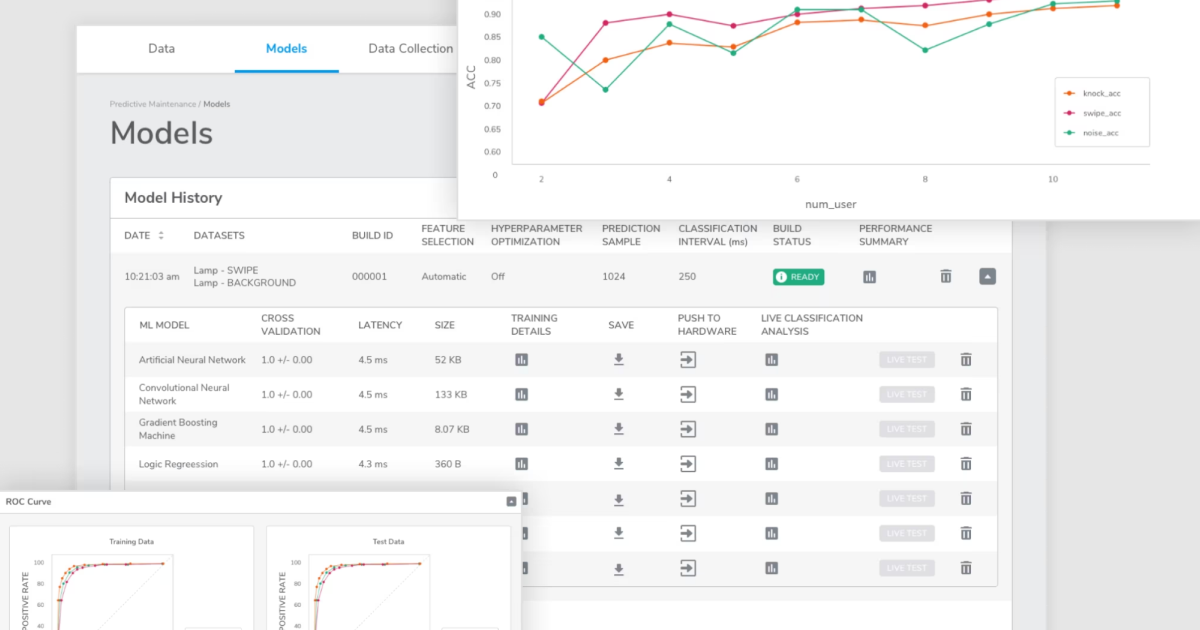

EcoStruxure is Schneider Electric's IoT-enabled, open and interoperable system architecture and platform that delivers Innovation At Every Level across connected products, edge control and apps, analytics, and services. The EcoStruxure architecture enables scalable design and operation of connected systems with best-in-class cybersecurity built in at every layer.

"While Nigeria is the world's eighth largest producer and exporter of crude oil, we still import nearly 80 percent of our petroleum products," said Devakumar V. G. Edwin, group executive director, strategy, capital projects and portfolio development, Dangote Industries. "Once completed in 2019, however, the Dangote Refinery will be the world's largest single train refinery capable of producing 33 million tons of various liquid products, including gasoline, diesel, kerosene, aviation fuel and other petrochemicals every year. Not only is that enough to meet all of Nigeria's consumption needs each and every day, we will have a surplus of each of these products for export."

Because it will be a single train facility, any interruption or shutdown in operations at the Dangote Refinery would decrease output from 650,000 barrels a day to zero. Recognizing the need to safeguard their continuous operations, Dangote Oil Refinery Ltd. chose Schneider Electric's EcoStruxure Foxboro DCS and Triconex process safety solutions—which include emergency shutdown systems—to maximize the safety and efficiency of their operations and to improve the reliability of their equipment assets and asset sets. PIONIR process analyzers will improve process optimization, asset protection and compliance with environmental regulations. And advanced SimSci and Wonderware software will be implemented both to unify planning and scheduling and to improve real-time data collection and analysis, further optimizing operations and product blending. When combined, the integrated suite of systems and software solutions will help the Dangote Refinery gain better real-time control of all its business variables, including the safety, reliability, efficiency and profitability of its operations.

"Maintaining continuously safe, reliable and efficient refinery operations will help us reach our national goal of reducing petroleum products imports and increasing our energy independence, which could help increase our country's foreign exchange by up to $5.5 million and reduce oil imports by up to $7.5 million," Edwin said.

As part of the agreement, Schneider Electric has created a task force between its Nigerian office and its engineering office in India, which has successfully implemented critical control and safety systems for some of the largest refineries in the world. This level of experience and expertise, coupled with Schneider Electric's commitment to providing local support, made the company Dangote's top choice. Schneider Electric will also provide design, engineering and installation services, not only ensuring a successful implementation from start to finish, but ensuring the workforce is equipped with the tools they need to positively impact business performance.

"Today's industrial operations are facing two critical challenges: the increasing speed of business and the pace of technology changes, particularly in the day of IIoT," said John Eva, SVP, global engineering, procurement and construction, Schneider Electric. "To help Dangote address these challenges, we are delivering and implementing value-focused technology solutions—innovation at every level—so they can move from managing their performance and business results to actually controlling them, in real time."

Ken Briodagh is a writer and editor with more than a decade of experience under his belt. He is in love with technology and if he had his druthers would beta test everything from shoe phones to flying cars.Edited by

Ken Briodagh