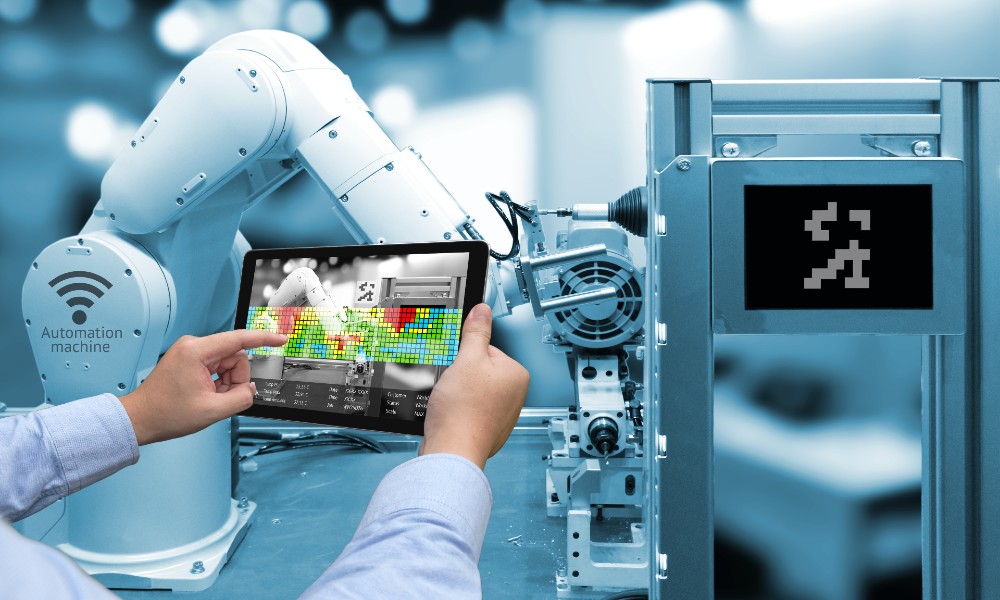

What is a smart factory? It is a flexible system that can self-optimize performance across a broader “network, self-adapt and learn from new conditions in real or near-real time, and autonomously run entire manufacturing processes.

The manufacturing industry is very conservative when it comes to the introduction of cutting-edge technologies and innovations. Most factories maintain and use their equipment for years. Replacement could be very pricey and smaller industrial companies cannot afford the capital expense especially if existing machines work well.

There are a lot of moving parts that make the factory smart and utilizing wireless technologies is one of such parts. While wireless technologies have been around for more than four decades, the modernization of industrial networks, the development of different protocols and the acceptance of the Industrial Internet of Things (IIoT) principles has accelerated demand for use of wireless technologies on factory floor.

Wireless technologies offer many benefits to a manufacturing facility such as mobility and free movement leading to a greater flexibility in configuring the factory floor. Minimizing or eliminating the amount of expensive cabling on factory floor or ceiling. Wireless technologies allow for quicker and easier installation that leads to new line configurations, easy network device integration and reduction of the installation time. Not to mention the increased personal safety in the use Human Interface Devices (HID).

However, walls, glass, electrical/radio frequency interference in usual factory settings can disrupt wireless signals. Harsh radio environment and high level of device density compromises network reliability within factories. Challenges to wireless signal propagation include such things as rapid temperature changes, humidity, moisture, shock, vibration, signal reflection, and interference from plant components such as ductwork, vehicle cages, electrostatic machines, and cable shielding.

Understanding how RF platforms work in these harsh environments is the first step toward designing and deploying reliable wireless networks that can provide data that can improve plant productivity and efficiency.

How can a factory ensure the connectivity to minimize the downtime and maximize its production? James Brehm & Associates white paper titled “The Wireless Internet of Things (IoT) Is Destined to Make Factories Smarter” is available for download to answer y

This paper also discusses how wireless technologies can impact a manufacturing environment, the challenges factory operators face to meet their increasing demands and how network testing comes to rescue to help in ensuring business continuity.

Edited by

Maurice Nagle